Aluminum cladding is much lighter than most other cladding options

Author:Jayminton Time:2024-05-22

The aluminum sheets used for cladding are produced from aluminum alloy plates. The alloying elements like manganese, magnesium, and zinc are added to pure aluminum to give it greater strength and durability. The alloyed aluminum is rolled into thin sheets that can be cut and bent into the desired cladding shapes.

Aluminum sheathing, composed of slender sheets of this metal, envelops a structure’s facade. Yet, when we talk about buildings and their protective layers, we’re essentially discussing how these thin plates become an integral part of an edifice’s outer persona.

Unlike load-bearing walls, aluminum Cladding is not a structural element. Its purpose is to create an outer shell that shields the building from the weather and also defines architectural aesthetics. It serves as a second skin that wraps around a building’s structural core.

Aluminum cladding is very different from other forms of cladding like brick, wood, stucco, and vinyl. Key differences include:

- Aluminum cladding is much lighter than most other cladding options. This makes it easier to transport and install.

- It is very durable and corrosion-resistant compared to wood and stucco cladding.

- Aluminum spreads less fire compared to vinyl cladding.

- It provides better insulation than brick or concrete cladding.

Aluminum cladding comes in a wider range of cgreater finishes versus materials like concrete

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

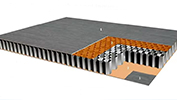

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US