Production Process of Wood Grain Aluminum

Author:Jayminton Time:2024-06-14

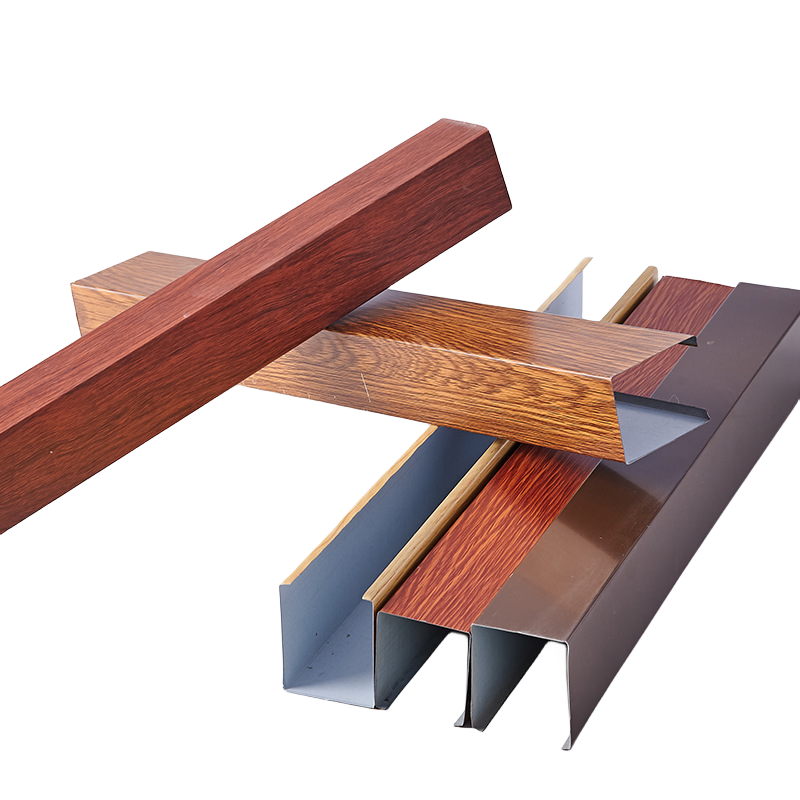

The powder coating wood grain process is a sublimation process, using pressure and heat combined. The decorative patterns of faux wood grain are transferred into powder coated surfaces that have been completely cured. Aluminium. Anodizing. Extrusion.

Wood grain transfer profiles refer to the process of transferring and penetrating the wood grain pattern on the transfer paper or transfer film onto the sprayed profiles quickly through heating and pressurization based on the principle of high-temperature sublimation and thermal penetration on the basis of electrostatic powder spraying. The produced wood grain profiles have clear textures, strong three-dimensional sense, and can better reflect the natural feeling of wood grain. They are ideal energy-saving and environmentally friendly materials to replace traditional wood.

Wood grain has strong adhesion to aluminum, is non-toxic, odorless, and easy to clean. The product has clear and realistic textures, strong three-dimensional sense, good appearance decoration effect, and has a visual effect of returning to nature. The coating on the surface of the electrostatically sprayed aluminum profile does not volatilize or oxidize in the air, and does not pollute the environment. The dirt deposited on the sprayed surface can be restored to its original gloss and appearance once cleaned.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US