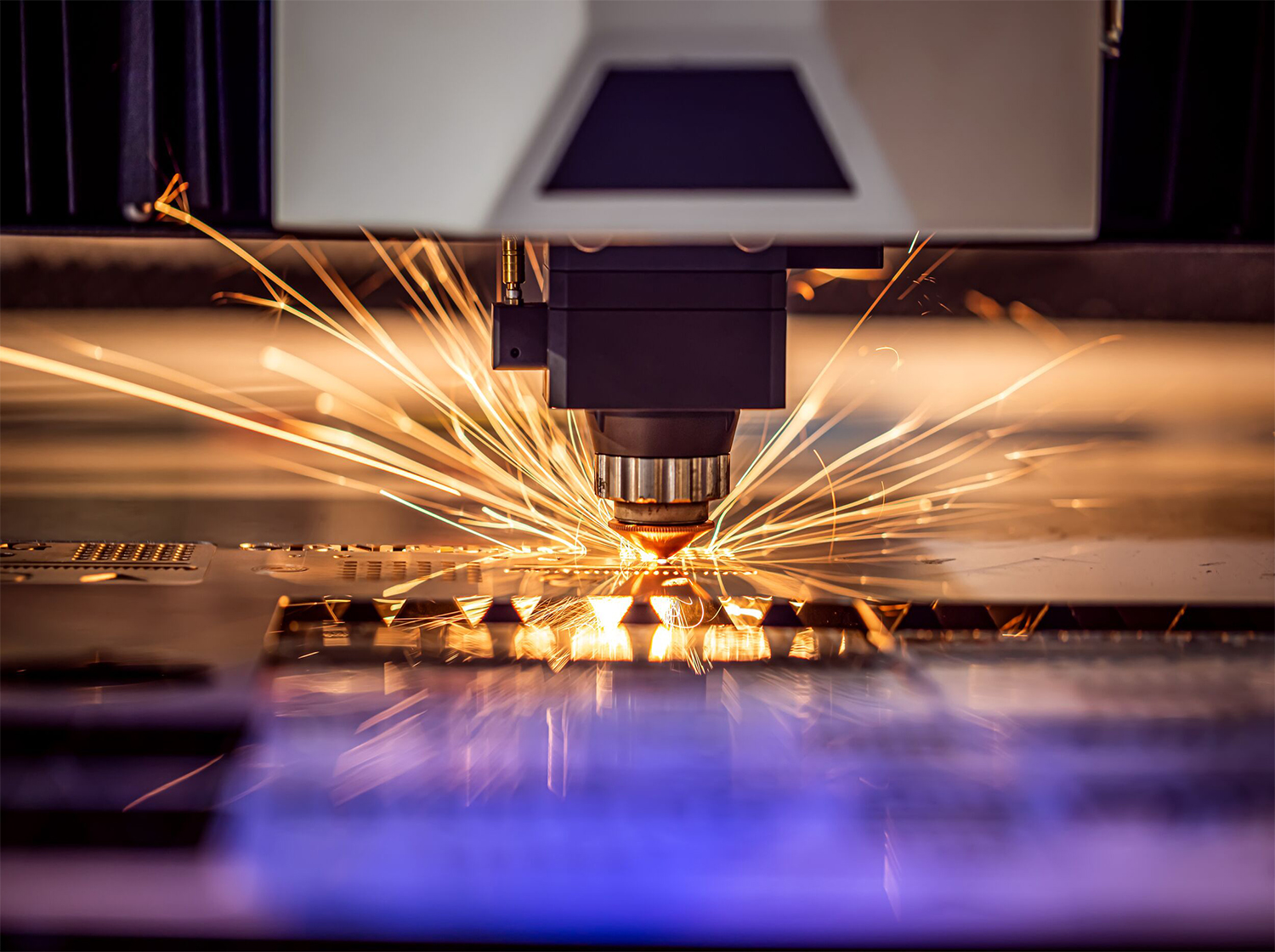

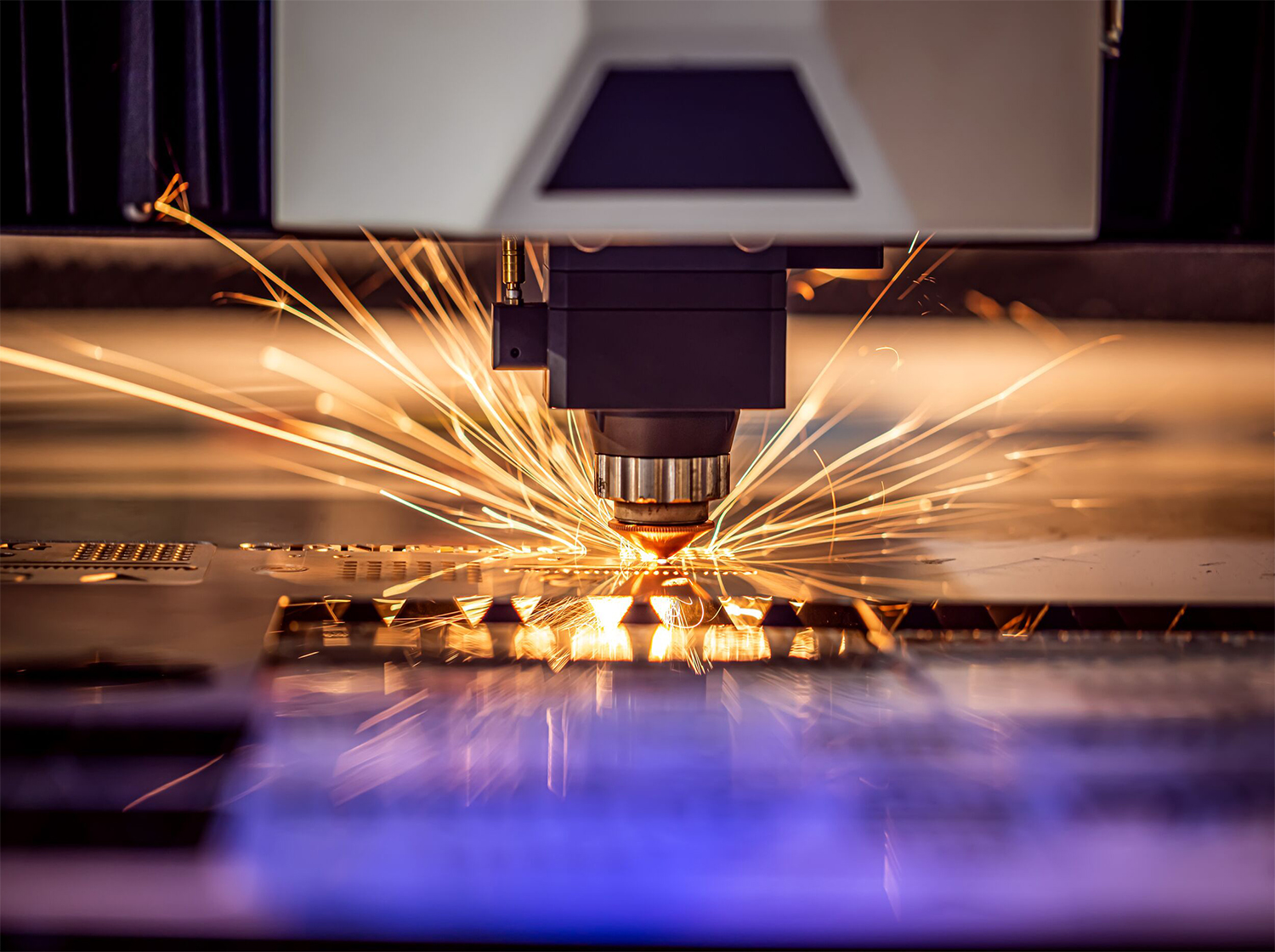

In the realm of modern architecture and interior design, aluminum decorative boards have emerged as versatile elements that blend aesthetic appeal with functional utility. Central to their production is laser cutting technology, which has revolutionized the way these boards are crafted and utilized in various architectural applications. This article explores the profound impact of laser cutting technology on aluminum decorative boards, highlighting its capabilities, benefits, and implications for contemporary design.

Precision and Intricacy:Laser cutting technology stands out for its unparalleled precision and ability to create intricate designs on aluminum sheets. Unlike traditional cutting methods, which may be limited in detail and scope, laser cutting allows for the realization of complex patterns, geometric shapes, and fine details with exceptional accuracy. This capability opens up a world of design possibilities, enabling architects and designers to incorporate elaborate motifs, customized patterns, and unique textures into aluminum decorative boards.

Versatility in Design:One of the key advantages of laser cutting technology for aluminum decorative boards lies in its versatility. Whether used for Wall Cladding, Ceiling Panels, partitions, or decorative screens, laser cutting can adapt to diverse design requirements and architectural styles. Designers can experiment with various patterns, perforations, and cutouts to achieve desired visual effects and functional outcomes, thereby enhancing the aesthetic appeal and spatial dynamics of interior and exterior spaces.

Efficiency and Productivity:Beyond its creative potential, laser cutting technology offers significant advantages in terms of efficiency and productivity in the manufacturing process of aluminum decorative boards. The precision of laser cutting minimizes material waste, optimizes production timelines, and facilitates rapid prototyping and customization. This efficiency not only streamlines the manufacturing process but also supports sustainable practices by reducing resource consumption and environmental impact.

Enhanced Durability and Performance:In addition to aesthetic benefits, laser cutting technology contributes to the durability and performance of aluminum decorative boards. The clean, sealed edges produced by laser cutting minimize susceptibility to corrosion and enhance the boards' resistance to environmental factors such as moisture and UV radiation. Furthermore, the precision of laser cutting ensures structural integrity, promoting longevity and reliability in architectural applications.

Integration of Advanced Materials and Finishes:Laser cutting technology accommodates a wide range of aluminum alloys and finishes, allowing for seamless integration of advanced materials and surface treatments. Whether opting for powder coating, anodizing, or specialized finishes, designers can enhance the visual appeal, texture, and color palette of aluminum decorative boards to complement specific design schemes and project requirements. This versatility in material selection and finishing options further expands the design flexibility and aesthetic diversity achievable with laser-cut aluminum boards.

Innovation and Future Trends:Looking ahead, the evolution of laser cutting technology continues to drive innovation and shape future trends in the realm of aluminum decorative boards. Advancements in laser technology, including increased cutting speeds, improved precision, and integration with digital design tools, promise to further push the boundaries of architectural creativity. Moreover, the incorporation of sustainable practices and smart technologies into laser cutting processes reflects ongoing efforts to meet evolving environmental standards and client expectations in the design industry.

Conclusion:In conclusion, laser cutting technology represents a transformative force in the production and application of aluminum decorative boards within contemporary architecture and interior design. By combining precision craftsmanship with creative freedom, laser-cut aluminum boards not only elevate aesthetic standards but also enhance functionality, sustainability, and architectural innovation. As design trends evolve and technological capabilities expand, the role of laser cutting technology in shaping the built environment will continue to define new possibilities and inspire visionary solutions in architectural design.