Aluminum Ceiling Technical Specifications: Versatility and Performance

Author:Jayminton Time:2024-06-24

Aluminum Ceilings are renowned for their versatility, aesthetic appeal, and functional benefits in various architectural and interior design applications. Understanding their technical specifications is crucial for selecting the right product to meet design requirements and performance expectations. Here’s an in-depth look at the technical specifications of aluminum ceilings:

Material Composition and Characteristics

Aluminum ceilings are typically composed of high-quality aluminum alloys, chosen for their lightweight nature, durability, and resistance to corrosion. Common alloys used include 3000 series (alloyed with manganese) and 5000 series (alloyed with magnesium). These alloys offer excellent formability, allowing manufacturers to create diverse ceiling designs.

Thickness and Panel Dimensions

Aluminum Ceiling Panels are available in various thicknesses to accommodate different structural requirements and aesthetic preferences. Standard thicknesses range from 0.5mm to 3.0mm, with thicker panels providing enhanced durability and acoustic properties. Panel dimensions vary widely, offering flexibility in design and installation options.

Surface Finishes and Coatings

Aluminum Ceiling Panels are available in a range of surface finishes and coatings to achieve desired aesthetics and performance characteristics:

- Natural Finishes: Untreated aluminum with a natural metallic appearance.

- Anodized Finishes: Electrochemically treated to enhance corrosion resistance and provide color options such as clear, bronze, or black.

- Powder Coatings: Applied electrostatically and cured under heat to create a durable, scratch-resistant finish in various colors and textures.

The choice of finish depends on factors such as environmental exposure, design requirements, and maintenance preferences.

Acoustic and Fire Performance

Many Aluminum Ceiling Panels are designed to improve acoustic comfort by incorporating perforations or acoustic backing materials. perforated panels can achieve specific sound absorption coefficients, contributing to a quieter and more comfortable indoor environment. Additionally, aluminum ceilings can be engineered to meet fire safety standards, providing essential fire resistance in commercial and public buildings.

Installation Systems

Aluminum ceilings offer versatile installation systems to suit different ceiling designs and installation methods:

- Lay-in Systems: Panels are laid into a visible or concealed grid system, allowing for easy access to plenum spaces above.

- Clip-in Systems: Panels are clipped into a concealed suspension system, providing a seamless and clean aesthetic.

- Linear Systems: Panels are installed in continuous linear configurations, offering a sleek and modern appearance.

These systems facilitate efficient installation and maintenance, making aluminum ceilings suitable for both new construction and renovation projects.

Environmental Sustainability

Aluminum is inherently sustainable due to its recyclability and energy-efficient production processes. Recycled content can be incorporated into aluminum ceiling panels, reducing environmental impact and contributing to green building certifications such as LEED (Leadership in Energy and Environmental Design).

Applications

Aluminum ceilings find application in a wide range of environments, including:

- Commercial Buildings: Offices, retail spaces, airports, and hotels benefit from their aesthetic appeal and performance attributes.

- Educational Facilities: Schools and universities utilize aluminum ceilings for durability and acoustic control.

- Healthcare Settings: Hospitals and clinics appreciate their cleanability and hygienic properties.

- Residential Projects: Modern homes integrate aluminum ceilings for their contemporary look and maintenance ease.

In conclusion, understanding the technical specifications of aluminum ceilings is essential for architects, designers, and builders seeking to achieve functional and aesthetically pleasing ceiling solutions. By selecting the appropriate material composition, thickness, finish, and installation system, stakeholders can ensure optimal performance and longevity in their architectural projects. Aluminum ceilings not only enhance indoor environments but also contribute to sustainable building practices, making them a preferred choice in modern construction and design.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

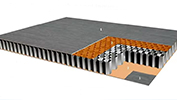

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US