Crafting Quality: The Production Process of Aluminum Decorative Boards

Author:Jayminton Time:2024-07-24

Aluminum decorative boards have become a popular choice in contemporary architecture and interior design due to their versatility, durability, and aesthetic appeal. These boards are used for various applications such as Wall Cladding, Ceiling Panels, and decorative screens. The production process of aluminum decorative boards involves several key steps that ensure high quality and precision in the final product.

1. Material Selection:The production of aluminum decorative boards begins with the careful selection of raw materials. High-quality aluminum sheets are chosen based on their thickness, alloy composition, and surface finish. These sheets are typically sourced from reputable suppliers who meet stringent quality standards.

2. Surface Preparation:Before undergoing any further processing, the aluminum sheets undergo surface preparation to ensure cleanliness and adhesion of subsequent coatings or finishes. This may involve cleaning, degreasing, and etching processes to remove any contaminants and create a suitable surface for finishing.

3. Coating Application:One of the critical steps in the production process is the application of coatings or finishes to the aluminum sheets. Depending on the desired aesthetic and functional properties, various coating methods such as powder coating or PVDF (polyvinylidene fluoride) coating are used. These coatings not only enhance the appearance of the boards but also provide protection against corrosion, UV radiation, and weathering.

4. Cutting and Shaping:Once the coating has been applied and cured, the aluminum sheets are cut into the desired shapes and sizes. Advanced cutting techniques such as laser cutting or CNC (computer numerical control) routing are employed to achieve precision and intricate designs as per architectural specifications.

5. Perforation and decoration:For decorative panels or screens, perforation is often applied to the aluminum sheets. This process involves punching holes of various sizes and patterns using specialized equipment. perforated panels not only add visual interest but also offer functional benefits such as improved acoustics and airflow in architectural applications.

6. Quality Control and Inspection:Throughout the production process, rigorous quality control measures are implemented to ensure that each aluminum decorative board meets the specified standards for dimensional accuracy, surface finish, and durability. Inspection processes may include visual inspections, measurements, and testing of coating adhesion and mechanical properties.

7. Packaging and Delivery:Once production and quality checks are complete, the finished aluminum decorative boards are carefully packaged to protect them from damage during transportation and storage. Packaging materials may include protective films, edge protectors, and pallets to ensure safe delivery to construction sites or distribution centers.

8. Installation and Maintenance:Upon arrival at the installation site, aluminum decorative boards are installed according to architectural plans and specifications. Proper installation techniques are crucial to ensure structural integrity and longevity of the boards. Regular maintenance, such as cleaning and inspection, helps preserve the appearance and performance of aluminum decorative boards over time.

In conclusion, the production process of aluminum decorative boards involves a series of meticulous steps—from material selection and surface preparation to coating application, cutting, perforation, quality control, and packaging. Each step contributes to the creation of high-quality, aesthetically pleasing architectural elements that enhance the built environment with their durability, versatility, and design flexibility. As demand for sustainable and visually appealing building materials continues to grow, aluminum decorative boards remain a preferred choice for architects, designers, and builders worldwide.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

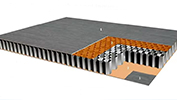

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US