Decoration Mesh Perforated Aluminium Perforated Facade Cladding

Author:Jayminton Time:2024-06-12

Bridging the gap between art and engineering, decoration mesh perforated aluminium perforated facade cladding systems are designed, engineered, and manufactured with quality, integrity, and excellence. Utilizing laser cutting aluminum panels for decorative facade cladding is a strong and impactful design statement for your project.

Decoration mesh perforated aluminium perforated facade cladding provides a canvas with endless possibilities. By utilizing a “field pattern” with small repeating geometric shapes, one can “overlay” a larger image, brand element, or contrasting pattern to achieve a never—before achievable design impact.

Decoration mesh perforated aluminium perforated facade claddings have been used in some of the most iconic buildings around the world due to their durability, aesthetic appeal, and longevity. These panels play a critical role as the first line of defense against external forces such as wind and rain; therefore, the appropriateness of the design and resilience of aluminum Cladding panels must be ensured. Previous researchers have conducted very minimal research on aluminum panels subjected to windborne debris impact. Their scope was limited to studying the response of panels when they are targeted at the center. The influence of various structural and load-related parameters on the response of such claddings has yet to be investigated. Furthermore, no design guidelines are readily available that engineers can use to predict the response of aluminum cladding panels when subjected to such loads considering various conditions (location of impact, projectile’s material, angle of impact, velocity of impact, unsupported length, and the geometry of the panels). The main aim of this paper was to develop some design guidelines that engineers can use to predict the response of aluminum cladding panels exposed to windborne debris impact. To achieve this, a series of parametric studies was conducted to generate a data bank. These parametric studies were performed with the help of a robust numerical model that has been validated with experimental results. The parametric sensitivity study revealed that the angle of impact was the most influential parameter, causing an 80% reduction in the peak impact force with a 50% decrease in the angle. The velocity, plate thickness, location of impact, and unsupported length also significantly influenced the panel’s response. The alloy type emerged as a dominant factor affecting the maximum and residual deflections. Regression equations were formulated based on the generated dataset to accurately predict the peak impact force, maximum central deflection, and residual deflection of solid aluminum cladding panels. The proposed prediction equations offer a better alternative to experimental testing.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

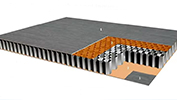

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US