Exploring the Versatile Applications of Aluminum Honeycomb Panels

Author:Jayminton Time:2024-08-02

Aluminum Honeycomb panels have emerged as a versatile and innovative solution in various industries, revolutionizing the way we approach construction, transportation, and manufacturing. With their unique structural properties and exceptional performance characteristics, these panels have found extensive applications across a wide spectrum of sectors, each benefiting from their lightweight nature, durability, and design flexibility.

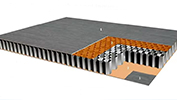

Understanding aluminum honeycomb panels

Aluminum Honeycomb Panels consist of a core structure made of hexagonal aluminum honeycomb cells sandwiched between thin aluminum alloy sheets. This sandwich construction provides a combination of strength and lightness that surpasses traditional materials. The core structure not only reduces weight but also enhances rigidity and stability, making Aluminum Honeycomb Panels ideal for demanding applications where strength-to-weight ratio is crucial.

Applications Across Industries

Aerospace and Aviation:In the aerospace industry, weight reduction is paramount to improving fuel efficiency and performance. Aluminum Honeycomb Panels are extensively used in aircraft interiors, cabin partitions, flooring, and bulkheads. Their lightweight nature contributes to overall weight savings without compromising structural integrity, making them indispensable for modern aircraft design.

Architecture and Construction:Aluminum honeycomb panels are favored in architectural applications due to their aesthetic appeal and practical benefits. They are used in building facades, curtain walls, and interior partitions where a combination of lightweight construction, durability, and design flexibility is required. The panels can be easily customized in terms of size, shape, and surface finish, allowing architects to achieve unique design concepts while meeting performance standards.

Transportation and Automotive:In the automotive industry, aluminum honeycomb panels find application in vehicle components such as car doors, roofs, and interior panels. Their lightweight yet strong structure helps in improving fuel efficiency and vehicle performance. Additionally, these panels are used in the construction of buses, trains, and marine vessels, contributing to reduced operational costs and enhanced structural integrity.

Industrial and Manufacturing:Industrial sectors utilize aluminum honeycomb panels for a variety of applications including machinery enclosures, equipment housing, and modular structures. The panels provide excellent thermal and acoustic insulation properties, making them suitable for cleanroom walls, acoustic enclosures, and industrial partitions. Their corrosion-resistant properties ensure longevity and minimal maintenance requirements, even in demanding industrial environments.

Furniture and Interior Design:Within interior design and furniture manufacturing, aluminum honeycomb panels are valued for their lightweight construction and modern aesthetic. They are used in furniture components, decorative panels, and lightweight shelving systems, offering a blend of functionality and contemporary design.

Advantages and Future Prospects

The widespread adoption of aluminum honeycomb panels can be attributed to several key advantages:

- Lightweight Construction: Significant weight savings compared to solid materials, contributing to energy efficiency and reduced transportation costs.

- High Strength-to-Weight Ratio: Provides robust structural support while minimizing material usage.

- Design Flexibility: Easily customizable to meet specific design requirements, including size, shape, and surface finish.

- Thermal and Acoustic Insulation: Offers effective insulation properties, enhancing comfort and energy efficiency in various applications.

- Durability and Longevity: Resistant to corrosion, weathering, and wear, ensuring prolonged service life with minimal maintenance.

Looking forward, the versatility and performance of aluminum honeycomb panels continue to drive innovation across industries. As advancements in material science and manufacturing techniques evolve, these panels are expected to play an increasingly integral role in shaping the future of lightweight, sustainable, and high-performance structures worldwide.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US