The Advantages of Lightweight Aluminum Honeycomb Panels

Author:Jayminton Time:2024-08-02

In the realm of modern construction and manufacturing, materials play a pivotal role in shaping the efficiency, durability, and sustainability of products. Among these, lightweight Aluminum Honeycomb panels have emerged as a revolutionary solution, offering a myriad of advantages across various industries. From aerospace engineering to architecture, these panels have redefined the standards of structural integrity and efficiency.

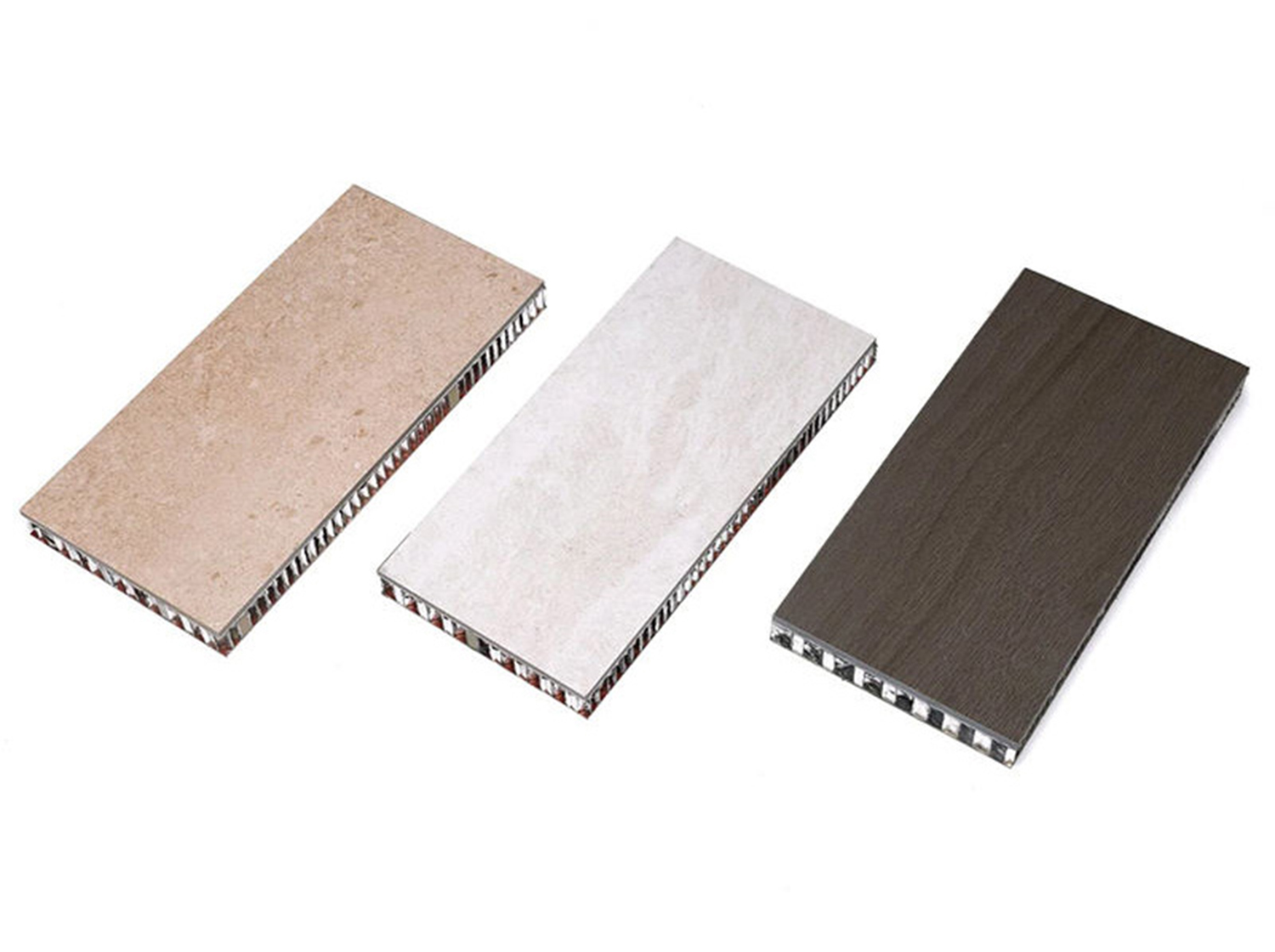

What are aluminum honeycomb panels?

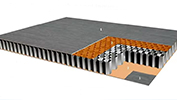

Aluminum Honeycomb Panels are composite structures consisting of two thin aluminum alloy sheets bonded to a lightweight honeycomb core made of aluminum, plastic, or other materials. The resulting sandwich structure provides high strength-to-weight ratio, rigidity, and impressive durability.

Advantages:

Weight Efficiency:One of the most notable advantages of Aluminum Honeycomb Panels is their exceptional weight efficiency. By incorporating a honeycomb core, the panels achieve significant reductions in weight compared to solid aluminum sheets or other traditional materials. This characteristic makes them particularly desirable in industries where weight savings translate directly to improved performance and efficiency, such as aerospace and transportation.

High Strength-to-Weight Ratio:Despite their lightweight nature, aluminum Honeycomb Panels boast remarkable strength. The honeycomb core structure distributes loads evenly across the panel, enhancing its ability to withstand bending, compression, and shear forces. This makes them suitable for applications where structural integrity is critical, including building facades, interior partitions, and vehicle components.

Stiffness and Stability:The honeycomb structure provides inherent stiffness to the panels, ensuring minimal deformation under load. This stiffness contributes to the overall stability of structures and reduces the risk of vibrations or resonance, which can be advantageous in applications ranging from furniture construction to high-speed transportation.

Thermal and Acoustic Insulation:Aluminum honeycomb panels offer effective thermal and acoustic insulation properties. The honeycomb core acts as a barrier to heat transfer and sound transmission, making these panels ideal for applications where temperature control and noise reduction are important considerations.

Corrosion Resistance:Aluminum alloys are naturally resistant to corrosion, ensuring longevity and minimal maintenance requirements for honeycomb panels exposed to outdoor environments or harsh conditions. This corrosion resistance extends their lifespan and enhances their economic viability over time.

Design Flexibility:Aluminum honeycomb panels can be easily customized to meet specific design requirements. They are available in various sizes, thicknesses, and surface finishes, allowing architects, designers, and engineers to achieve aesthetic goals without compromising on performance or functionality.

Applications:

The versatility of lightweight aluminum honeycomb panels lends itself to a wide array of applications:

- Aerospace: Used in aircraft interiors, floors, and bulkheads to reduce weight while maintaining structural integrity.

- Architecture: Employed in building facades, curtain walls, and interior partitions for their aesthetic appeal and functional benefits.

- Transportation: Found in automotive components, marine vessels, and rail interiors to enhance fuel efficiency and performance.

- Industrial Equipment: Utilized in machinery enclosures, cleanroom walls, and modular structures due to their durability and ease of installation.

Conclusion:

Lightweight aluminum honeycomb panels represent a paradigm shift in material science, offering a compelling combination of strength, efficiency, and versatility. As industries continue to prioritize sustainability and performance, these panels are poised to play a pivotal role in shaping the future of construction, manufacturing, and beyond. Whether reducing fuel consumption in aircraft or enhancing architectural design possibilities, their impact is undeniable, making them a cornerstone of innovation in the 21st century.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US