What Is Laser Cutting Aluminum?

Author:Jayminton Time:2024-06-12

Laser cutting is among the most economically efficient, flexible and precise ways of cutting metal and is now more effective and simpler than ever. They are used wherever complex designs have to be processed accurately, quickly and with as little force as possible. The process is particularly popular in the industrial sector as it can be used to machine almost any metal. The powerful and cost-effective laser cutters from JustLaser are ideally suited for cutting metal up to 6 mm thick (ideally) and win people over with their low investment risk and high levels of productivity. Higher processing speeds and typical material strengths are between 0.5 mm to around 4 mm.

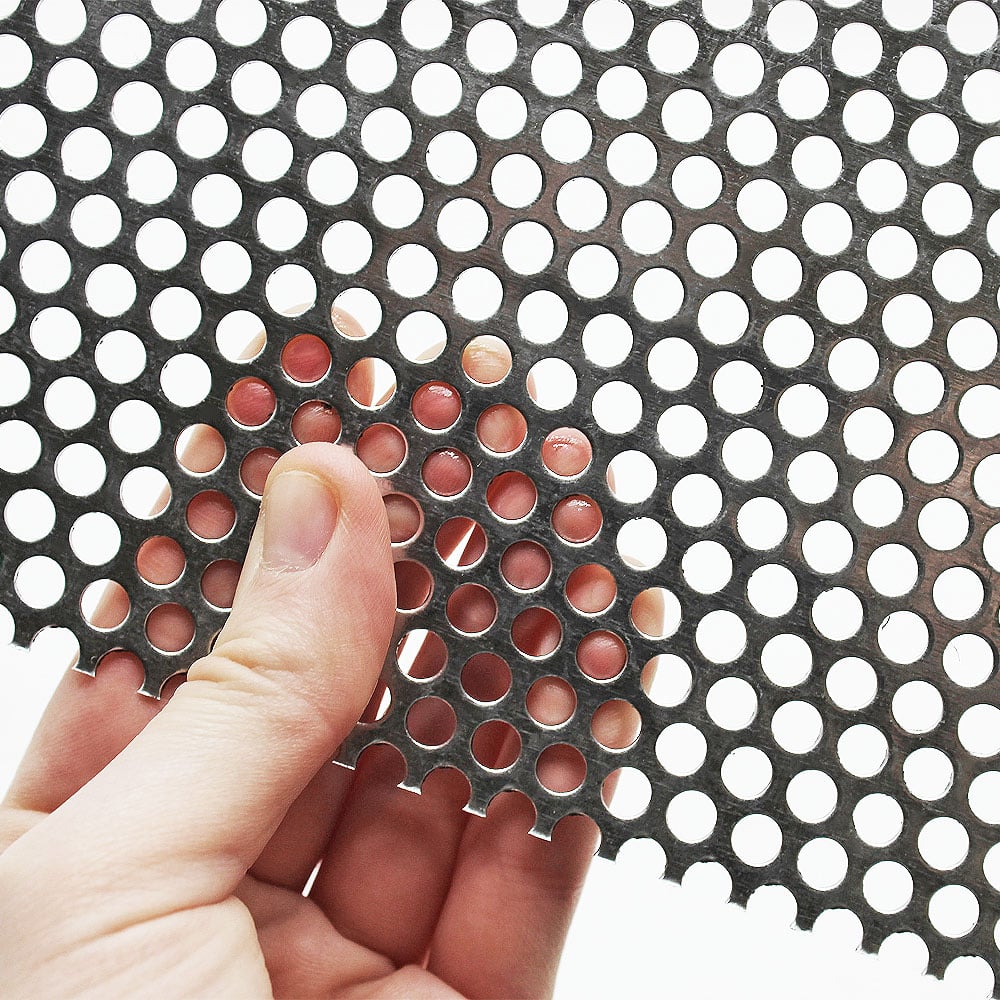

Laser cutting aluminum is a manufacturing process that uses a high-powered and tightly focused laser beam. This is to precisely cut aluminum sheets or plates to exactly match CAD-specified shapes or patterns. It is a critically important method for metal fabrication, offering major advantages over more traditional cutting techniques. Laser cutting aluminum is common in various industries, including aerospace, automotive, electronics, signage, and architectural applications. It offers a precise and efficient method for cutting aluminum with high quality and consistency.

The laser cutting of aluminum holds significant importance in virtually all manufacturing sectors. It offers both versatility and cost-effectiveness. The laser cutting of aluminum can take place on flat and formed parts or a wide spectrum of thicknesses and alloys, with a single operation. The materials wastage of laser cutting is also very low. Additionally, laser cut parts produced by a good set-up and appropriate equipment require minimal or no post-processing to produce an acceptable finish on the cut faces. This ultimately removes the need for additional manufacturing stages.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US