The Strength of Aluminum Honeycomb Panels: A Comprehensive Overview

Author:Jayminton Time:2024-08-20

When it comes to materials used in modern construction, aerospace, automotive, and industrial applications, the Aluminum Honeycomb panel stands out as a marvel of engineering. These panels are celebrated for their remarkable strength-to-weight ratio, which makes them an invaluable asset across various fields. But what exactly gives aluminum honeycomb panels their impressive strength? Let’s delve into the science and applications that showcase their extraordinary capabilities.

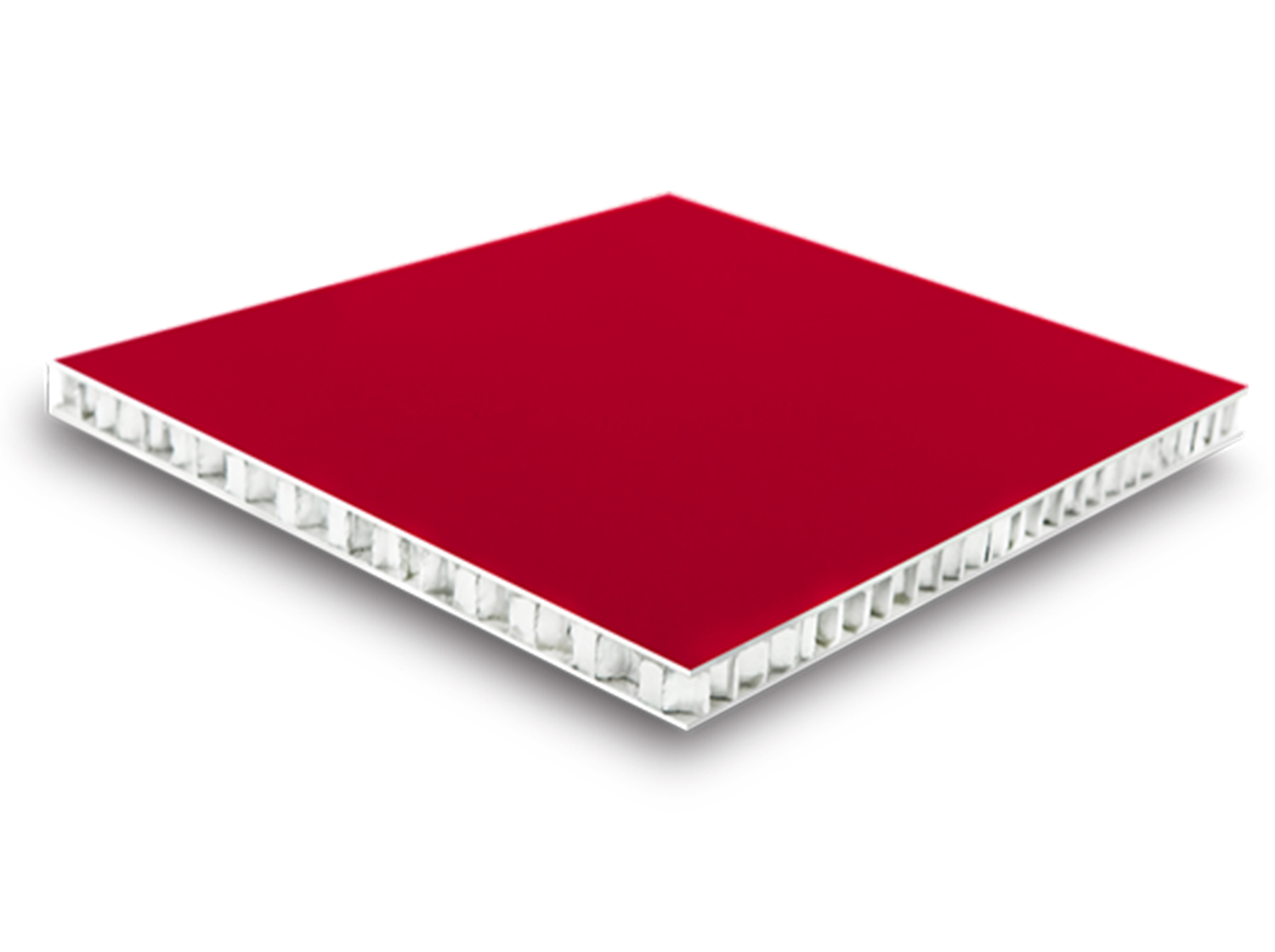

What is an Aluminum Honeycomb Panel?

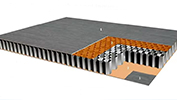

An aluminum honeycomb panel consists of two thin layers of aluminum that enclose a core of hexagonal honeycomb-structured cells. This design resembles a beehive, hence the name. The honeycomb core is usually made from aluminum, although other materials like Nomex or cardboard can also be used in specific applications. The aluminum sheets provide a protective outer layer, while the honeycomb core contributes to the panel’s structural integrity.

The Science Behind the Strength

**1. ** Strength-to-Weight Ratio:One of the most significant advantages of aluminum Honeycomb Panels is their exceptional strength-to-weight ratio. The honeycomb structure is both lightweight and incredibly strong due to the way forces are distributed across the cells. This design reduces the amount of material needed while maintaining structural stability, making the panels ideal for applications where weight is a critical factor.

**2. ** High Compression Strength:The honeycomb core excels in compression strength. When subjected to compressive forces, the hexagonal cells efficiently distribute the load, minimizing deformation. This characteristic is particularly beneficial in applications such as aircraft floors or automotive parts, where the panels must endure substantial stress without collapsing.

**3. ** Impact Resistance:Aluminum Honeycomb Panels also demonstrate impressive impact resistance. The honeycomb structure absorbs and disperses impact forces across a wide area, reducing the likelihood of localized damage. This makes them suitable for environments where panels are exposed to high-impact conditions, such as in transportation and industrial settings.

**4. ** Durability and Corrosion Resistance:Aluminum is naturally resistant to corrosion, which adds to the durability of honeycomb panels. The aluminum sheets and core are typically treated to enhance their resistance to environmental factors, ensuring that the panels maintain their strength and appearance over time.

**5. ** Thermal and Acoustic Insulation:Beyond strength, aluminum honeycomb panels offer excellent thermal and acoustic insulation properties. The honeycomb core helps in reducing heat transfer and noise, which is advantageous in various applications, from building facades to interior walls in commercial spaces.

Applications of Aluminum Honeycomb Panels

**1. ** Aerospace:In the aerospace industry, aluminum honeycomb panels are used extensively in aircraft construction. Their lightweight nature helps improve fuel efficiency, while their strength and durability ensure safety and performance.

**2. ** Automotive:The automotive sector benefits from aluminum honeycomb panels for manufacturing parts that require both strength and weight reduction. Components like interior panels and crash structures utilize these panels to enhance vehicle performance and safety.

**3. ** Construction:In construction, aluminum honeycomb panels are used for facades, partitions, and ceilings. Their strength allows for large, thin panels that can cover significant areas without compromising structural integrity.

**4. ** Marine:The marine industry also uses aluminum honeycomb panels in boat and ship construction. The panels’ resistance to corrosion and high strength make them ideal for harsh marine environments.

**5. ** Interior Design:Architects and interior designers leverage the panels for their aesthetic versatility. The lightweight and strong panels can be used in creative designs for walls, ceilings, and furniture.

Conclusion

The strength of aluminum honeycomb panels is a testament to modern engineering and material science. Their ability to combine lightweight properties with high strength and durability makes them a preferred choice in various demanding applications. As technology advances and industries continue to seek more efficient and sustainable materials, aluminum honeycomb panels are likely to play an even more prominent role in shaping the future of engineering and design.

Whether you’re flying in an aircraft, driving a car, or simply admiring a sleek building façade, aluminum honeycomb panels are a silent testament to the power of innovative material science, demonstrating that strength and efficiency can indeed go hand in hand.

S1 Clip-in Metal ceiling System

S1 Clip-in Metal ceiling System JMT-L4.2 U-Baffle System

JMT-L4.2 U-Baffle System JMT Aluminum Wall Cladding

JMT Aluminum Wall Cladding Aluminum Honeycomb Panel

Aluminum Honeycomb Panel Air-Condenser Cover

Air-Condenser Cover Metal Heat Cover

Metal Heat Cover Singapore Changi Airport T2 Arrival

Singapore Changi Airport T2 Arrival Australia Marvrl Stadium City Edge

Australia Marvrl Stadium City Edge Enterprise Information Announcement

Enterprise Information Announcement Construction Industry Solutions

Construction Industry Solutions About Jayminton

About Jayminton Contact US

Contact US